CTP plate Agfa Thermo Fuse

Most printing houses is faced with the problem of working with organic chemicals and their disposal. Meeting increasingly stringent standards and the care of the environment is an additional motive for crossing to the no chemical technology. Agfa offers a range of innovative solutions for working with no chemical plates grouped together under the patented name AGFA ThermoFuse.

By applying this technology with ease of operation, lower costs and reduced environmental impact can be achieved better stability and durability of the entire print production process.

The principle of thermo-technology AGFA Fuse

For standard, chemical CTP systems under the influence of light or temperature-sensitive laser illuminates the surface of the plate. The resulting image is not mechanically resistant and is necessary to develop a chemical process by which the board is prepared for printing. The final result (plate ready for printing) is dependent on a range of analog values such as: the state of chemistry and temperature, rate of passage of the plate through the developer, washing method, grommets and more.

No matter how the elements are controlled and kept within the standard values, final plates are reproducible only within certain tolerances.

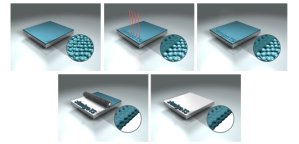

AGFA ThermoFuse technology uses the power of lasers to melt extremely small thermoplastic elements that are found in the surface layer of the plate. During illumination thermoplastic particles absorb heat and melt, joined together and formed solid areas which are firmly glued to the aluminum substrate. Dark areas remain in the initial state, and subsequently washed from the plate. With this process in one step we are getting stable and mechanically resistant plates ready for printing. In other words, the plate is fully formed in the process of illumination, and the whole process is 100% binary and dependent only on the laser settings. The only thing left after the illumination is to wash or rinse unexposed particles in areas where there are no pictures.

At the plates: Azura TS rinsing is carried out using water-based solution that includes a means for the grommets, which also serves to protect the plate, while the plates: Amigo TS uses a mild “Clean Out” liquid.

The benefits of technology ThermoFuse

Plates: Azura technology ThermoFuse does not require chemical process, but it is necessary to rinse them after illumination so it is not possible to say that the process is fully processles. Despite this, process brings many advantages over conventional chemical CTP technology and also the processles technology that is applied from other manufacturers:

- 100% binary process (eliminated the influence of chemical variables in development)

- Aluminum plate surface is mechanically resistant and suitable for a large number of prints

- Ease of Use

- The visible image of the finished plates (measuring wedge plates and checks before placing the printing press)

- Speed of lighting is almost identical like to the chemical CTP plates

- A large number of prints (Amigo TS plates without firing can provide up to 200,000 impressions, and with the baking much more)

- Environmentally friendly technologies

- Lower cost (less water and energy consumption)

- Possibility of archival records and reprints (rinsing is carried out with the aid of liquid containing means for grommets)

ThermoFuse technology was developed with the aim of saving and reducing the negative impact on the environment. Aluminum plates use very thin surface layer which is washed in an aqueous solution. Thermoplastic components (latex) are chemically inert. The chemical for rinse the rubber coating is pH neutral (pH value is very similar to the value of tap water) and does not contain alkaline and corrosive agents, and undesirable solvent.

Using ThermoFuse technology significantly reduces water consumption, probably one of the most important and most threatened resources.

Tested and proven technology

Agfa ThermoFuse is a proven technology. Agfa first introduced procesless plates for printing in 2000th: Thermolite, which have been used successfully in more than 100 different models of direct printing machines and excellent are accepted in the market.

Plates: Azura presented at Drupa 2004 are intended for use in standard thermal CtP devices with a laser wavelength of 830 nm.

In the middle of 2010 the new, improved generation of plates are introduced ThermoFuse (Azura TS and: Amigo TS). These plates provide an even greater number of prints, and improved lighting speed.

Existing users of chemical thermal CTP solutions relatively easily and with little investment can go on the boards of technology AGFA ThermoFuse. CTP device is not necessary to change (it is necessary to check the list of supported devices for the desired CTP plate type), or the necessary changes apply only to the process of developing. To work with the plates: Azura TS is necessary to buy a unit for washing while working with the plates: Amigo TS is possible with installation of appropriate brushes to use existing developer for CTP or conventional plates.